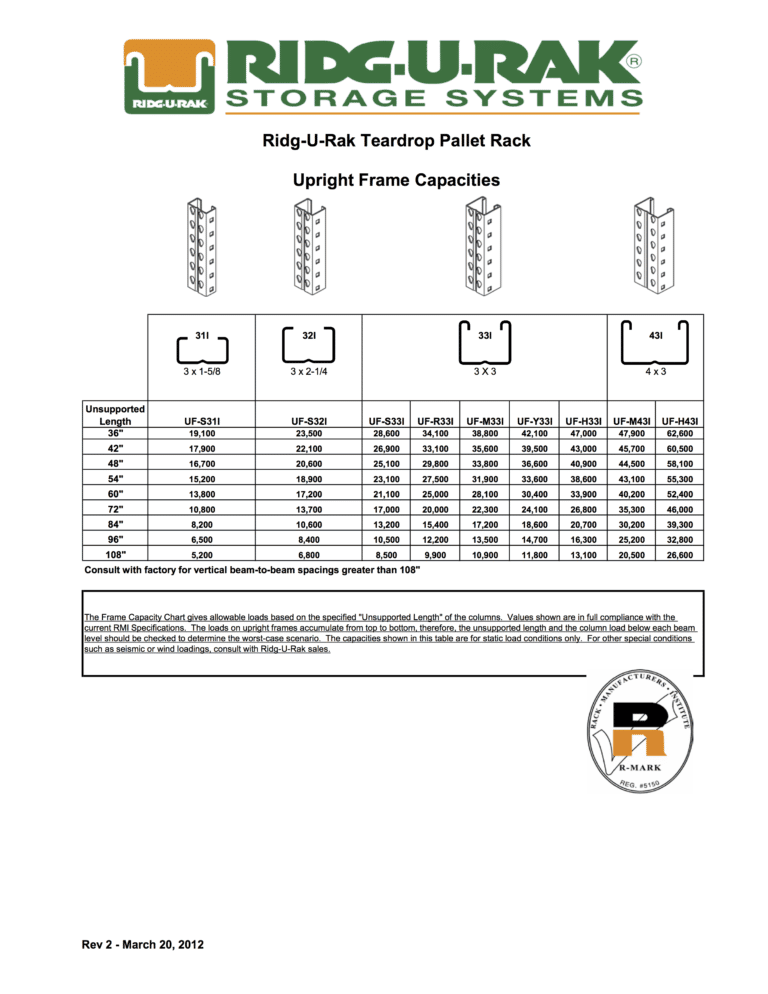

Their document ansi mh 16 1 2012 covers american warehouse racking weight limits and specifications that include specialized topics like pallet rack upright capacity and even teardrop pallet racking weight capacity.

Pallet rack weight capacity calculator.

Rack manufacturing institute rmi.

Using a professional pallet rack designer and engineer is the best way to get accurate calculations.

The more air space in the rack the less its capacity.

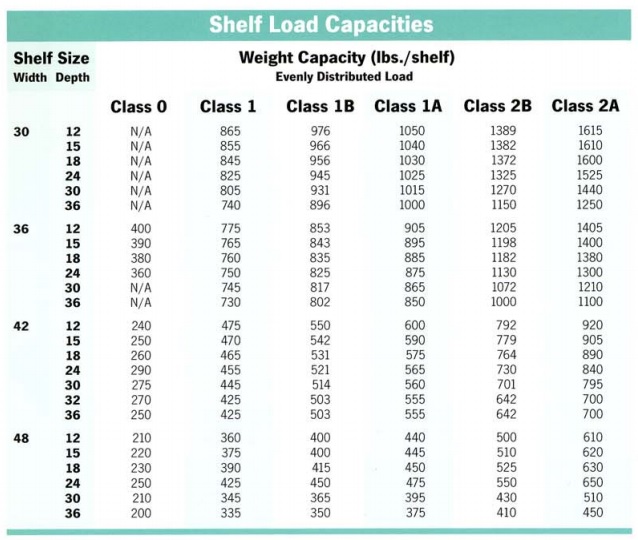

Capacities include 12 5 impact for two pallets side by side.

Pallet rack capacity labels are customizable to your racking and are highly visible reminders that improve warehouse safety.

This person can provide you with the allowable weight capacity from the international building code.

For a three pallet wide shelf the values should be multiplied by 0 95.

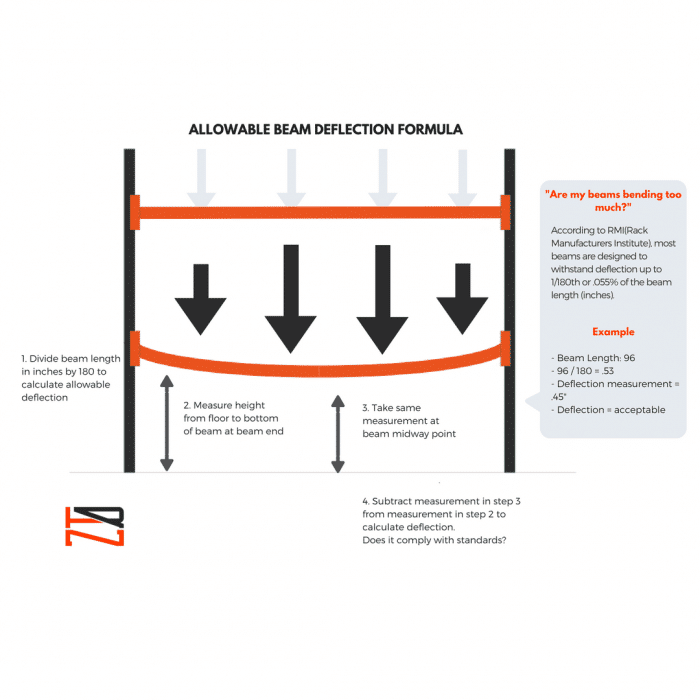

If your warehouse is located in a seismic area this can decrease the static capacity for a pair of load beams.

Each beam carries 50 of the load and assume proper installation and no beam damage.

Length of beam measured from inside of the collar to the inside of the collar.

The purpose of this pallet rack calculator is to estimate the non seismic capacity of a beam based on 3 dimensions.

The deflection limit for all pallet rack beams is the length divided by 180.

When you are configuring a pallet rack system there are two types of capacity to take into account.

Rack capacity is like a chain subject to.

Roll formed pallet rack beams that are longer than 150 require lateral ties.

Capacity chart is based on current rmi specifications.

All values for pallet rack beams are based on a uniformly distributed load i e.

Pallet rack load capacity calculation.

That includes engineers.

Because of a growing demand for greater warehouse safety in north america it is required to have and display the load capacity of your racks.

Every reputable pallet racking system manufacturer belongs to the rmi.

Warehouse rack has a team of experts that help you maximize your storage racking capacity and warehouse storage layout planning.

Getting those capacities right is a critical factor in safe efficient rack operations so understanding why they are very different numbers is important.

More beam levels means your rack can usually hold more total weight.

Once your racking is set up we advise putting capacity labels on it so forklift operators are aware of weight limits.

48 vertical spans are very typical in pallet storage applications although that can change for tall light loads or very short dense loads that require more structure to carry.

Gauge most beams are 16 gauge thick steel.